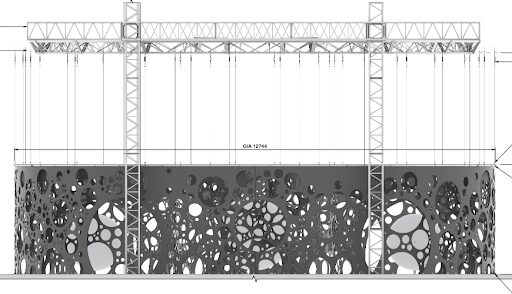

We were recently part of BrisFest Art Boat: The Spheres Art Installation. This project was a fusion of Art, Engineering and Expertise: our fabricators have spent years exploring the endless possibilities of plastic fabrication and we believe that we have created something spectacular. “The Spheres” is the most innovative and celebrated installation of BrisFest this year.

Most Brisbanites would have probably seen this larger-than-life floating art installation on the Brisbane River that Industrial Plastics created in partnership with a renowned art company.

In this article, we’ll explore the project origins and learn about the processes used and challenges overcome by our fabricators to bring this magnificent work to life.

The conceptualisation of “The Spheres” for the BrisFest Art Boat

The fact that Industrial Plastics was heavily involved in the project’s early stages by the stakeholders worked out well for everyone.

The suggestions made by our engineering team and fabricators on thickness selection, size of individual cylinders and design inputs for the assembly assisted the art company in developing a successful design that is both aesthetically pleasing and structurally sound.

In order to arrive at the design we have today, several prototypes were fabricated and a few design revisions were tested.

Fabrication

A total of 80 sheets of HDPE were used for the project and 130 butt welds were performed using our sophisticated sheet butt welding machine.

The fabrication methods used differ greatly from those we typically use. Due to the fact that the elements being welded are for artwork, extreme caution was taken during fabrication to avoid scratching any sheets. To safeguard the sheets from damage during processing, the sheets are completely masked on either side.

It was challenging to align the sheets during welding because the majority of the material was removed to form the circle design and this made the sheets get tangled with the welding machine; however, our fabricators employed their secret tools of the trade to overcome the issue.

Installation

Complicated projects like these not only require intricate fabrication processes but also require inventive packaging to facilitate transit and ease of installation. These cylinders are packed such that they may be unrolled with the greatest amount of control possible during installation, which reduced the number of personnel required to complete the task.

Meticulous project planning helped to identify and assess the risks during the early stages of the project and steps have been taken to eliminate or minimise their impact and deliver the project on time.

Contact us

“No job is too big or too small, only thinking makes it so”. At Industrial Plastics, we are determined to innovate our approach to fabrication by employing the most efficient technology, guaranteeing we make the highest quality plastic products available. Backed by our ISO:9001 accreditation, you can put 100% trust in our fabrication. If your project requires plastic fabrication please contact our technical sales team to assess your requirements. For more information contact us via [email protected] or call 1300 465 888.

Just Some of Our Customers