Industrial Plastics manufactured three sulphuric acid tanks for a client in the renewable energy industry. These tanks are designed and manufactured specifically for storing and recycling sulphuric acid, which is commonly used in creating phosphoric acid, phosphoric fertilisers, lead-acid batteries and other chemical compounds. Sulphuric acid is a harsh compound and is capable of dangerous reactions like the rapid oxidisation of metals and dilution with water which generates significant amounts of heat.

It’s imperative that your sulphuric acid is stored correctly and safely. This is why Industrial Plastics ensures that you receive the highest quality componentry, design and manufacturing.

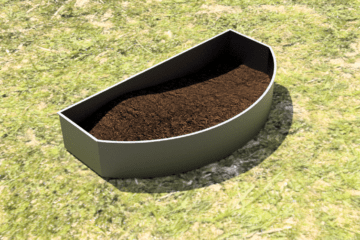

The two pictures above are an example of one of Industrial Plastics’ sulphuric acid tanks. These tanks are quite complex in regards to specifications and features. For this particular tank, the specifications are as follows;

- Operating volume: 15 kL

- Tank Material: Black HDPE

- Tank Size: 2900mm Dia x 4500mm High approx

- Material Thicknesses: Tank Roof: 25mm thick, Tank Wall: 25mm

Features:

- Conical floor, 2-stage (no solids build-up) to 200mm or less

- 1 x 1400mm removable hatch for agitator with wet seal moat

- 1 x side manway (630 O/D) with internal sloped insert

- 1 x roof inspection hatch 400mm

- 4 x baffles 20mm thick

- 1 x 180 overflow with elbow and dropper pipe.

- 4 x lifting lugs

- 1 x nameplate

- 19 x stub flanges with PP-coated backing ring

Our plastic fabrication projects guarantee our products are up to your tasks. The three sulphuric acid tanks underwent the following processes;

- Engineering analysis of a cylindrical HDPE tank design in relation to operational loading under Australian Standards.

- Finite Element Analysis (FEA) of the tank.

- Pressure testing against a maximum operating pressure of 42.5 kPa to eliminate the need to design, register and class as a pressurised vessel

- Creation of a Design Calculation Report

- Engineering certificate (RPEQ signed) covering verification and compliance of the above tank for the BML and PML applications

Contact Us

Industrial Plastics’ expertise is supported by our skilled staff who will exceed your expectations by using the latest fabrications methods and ISO quality assured processes. For more information on your own sulphuric acid tank, please contact us via [email protected] or call 1300 465 888.