Industrial Plastics recently collaborated with an architecture firm to design and fabricate several curved acrylic balustrade panels for a spiral staircase, as part of a million-dollar property on Moreton Island. Custom Acrylic Balustrade fabrications is the branch of plastic fabrication that is responsible for creating these eye-catching items.

Our acrylic fabricators at Industrial Plastics have spent years exploring the endless possibilities offered by the fusion of art and technology, and we believe we have found the balance once again with these staircase panels. When installed these balustrade panels curvature perfectly aligns with the staircase rails creating an impeccable design element inside the property.

Process Involved in balustrade panels fabrication

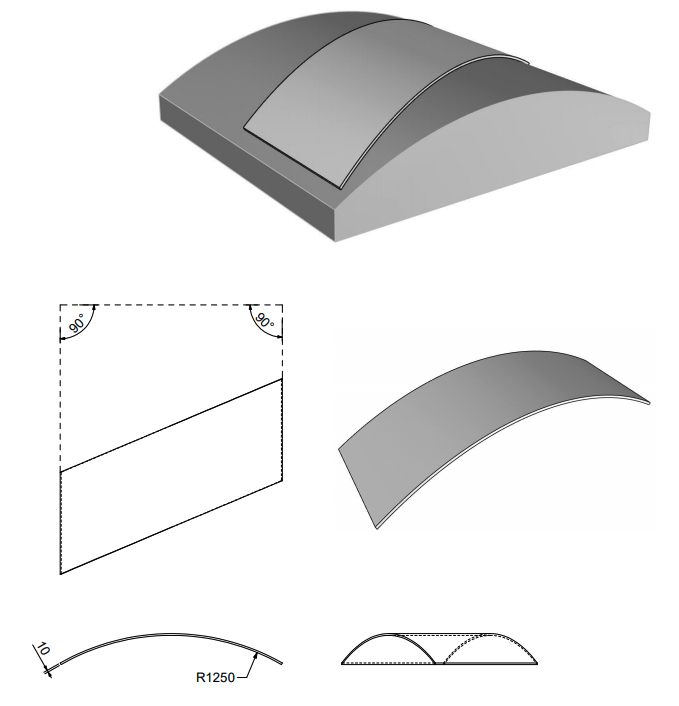

The process of acrylic fabrication involves heating a sheet of acrylic and transforming it into a completely different shape or form. To be specific the process involved in acrylic balustrade fabrication is called Drape forming.

It is a highly specialised process, used in acrylic fabrication to achieve gentle curves and shapes. After the sheet is softened in a moulding oven it will then be placed on a single mould where the sheet sags and moulds under its own weight or by the application of gentle pressure by an operator. This technique doesn’t stretch the sheet so that the finished part has uniform thickness and strength.

Keeping cost down

We strive to achieve premium quality products while minimising the costs involved. By having different size moulds at our disposal we can significantly reduce the time and cost involved in the project.

Tooling cost is also very economical for drape forming, which makes it a cost-effective option for smaller production runs.

How to order

To learn more about Custom Acrylic Balustrade Fabrications or If your project requires acrylic drape forming or blow moulding please contact our technical sales team to assess your requirements. For more information contact us via [email protected] or call 1300 465 888.