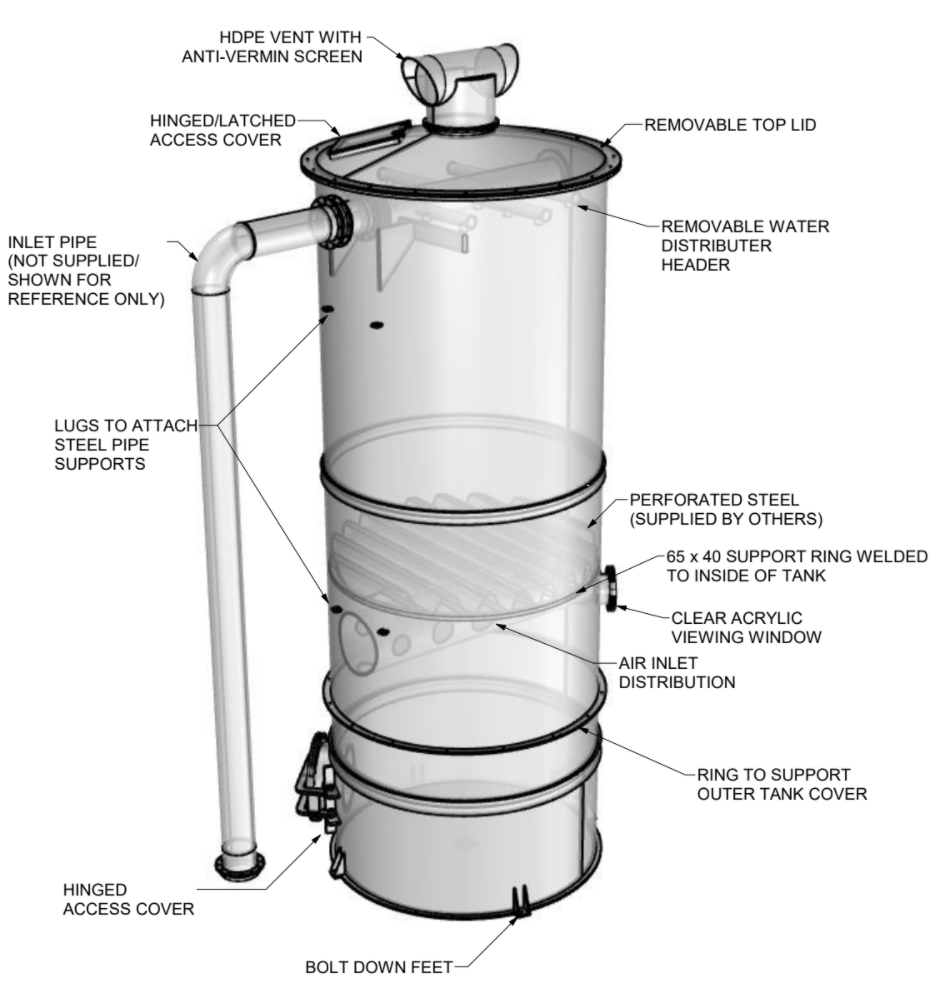

As HDPE fabrication specialists, Industrial Plastics has ample capacity to fabricate large scale, complex designs for our customers. Recently, a customer came to us with a challenging project that required the design and fabrication of two large aeration towers for use in a water treatment plant in New South Wales.

Challenges

The customer came to Industrial Plastics with a challenge, fabricate two full size aeration tanks with HDPE. This is unusual, as these products are traditionally fabricated from steel or FRP. Plastic was the chosen material as it would be low maintenance and corrosion/oxidisation resistant which is an important factor in a water treatment facility.

Past projects gave us the confidence to meet this challenge as we had built scrubbers before, just not to this magnitude. Taking the brief from the customer, the team came up with an initial design based on their expertise gained from working on similar projects and expanded upon it to meet the customers requirement.

Design

The customer supplied the basis for the initial design and Industrial Plastics managed the project through to delivery.

An initial review of the project requirements revealed a challenging aspect of multiple large ports in the tower cylinders. This issue needed to be addressed carefully for the long term structural integrity of the towers. The design team conducted verification checks with German engineering contacts and additionally engaged a local specialist engineering company to model the design and verify its long term suitability to the surrounding environment.

The Industrial Plastics team came up with a multi stage thickness design which was key in delivering a high-quality structural build. There were additional internal stiffeners that doubled as supports for the packing media to be later installed before use. With great attention to detail, the HDPE design was fully analysed, verified and certified by independent engineers to be fit for purpose and delivered a RPEQ sign-off before construction commenced.

Achievements

The advanced fabrication skills of the factory staff allowed for the successful delivery of the project. The fabrication marks a significant achievement for Industrial Plastics and the industry as a whole, with the towers being the first of their kind as large capacity HDPE aeration towers in Australia.

This project is just one example of many significant projects delivered by Industrial Plastics in 2021. The aim was to build something unlike others had before it, and with our measured approach we were able to convert a typically restrictive structure through a versatile, hard wearing and corrosion resistant material, HDPE PE 100.

We pride ourselves on delivering high-quality, long-lasting plastic solutions for our customers. For more information about our tank capabilities, please contact us via [email protected] or call 1300 465 888.