ABS – ABS (Acrylonitrile Butadiene Styrene) is are a hard, rigid and tough thermoplastic with good performance in a wide range of temperatures. Most famously used as LEGO bricks, ABS is also used as many car interior parts with it’s common “Leathergrain” and “Haircell” surface textures.

Acetal – The acetal is a synthetic polymer based on formaldehyde polymerization technology. It is characterized by good mechanical properties, including very good resistance to abrasion making it perfect for machining where

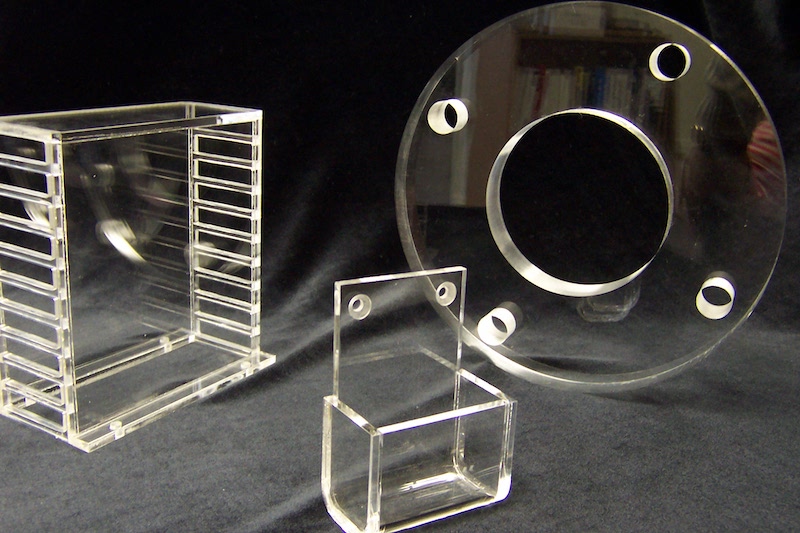

Acrylic – Also known as the trade name Perspex®, acrylic plastic sheet is a polyvalent and strong thermoplastic. Coloured, transparent, opaque or textured, acrylic is perfect for signs, bright banners, marketing collateral, displays, decoration, industrial parts and safety devices.

Nylon – Nylons are thermoplastic polyamides (PA). They have a high tensile strength making them very resistant to impact. Their strength also lends to use in mechanical parts applications

Polycarbonate – Plastic sheet made from Polycarbonate is thermoplastic and has a high molecular weight. They have exceptional impact strength under a variety of temperatures. Polycarbonate is characterised by a balance of strength and transparency. Also, they provide superior resistance to yellowing.

HDPE (Polyethylene) – HDPE plastic sheet is one of the most commonly fabricated thermoplastic polymers. Black (UV stable), Natural (white) or coloured, it is characterised by toughness, excellent chemical resistance and low coefficient of friction. HDPE has low moisture absorption and is commonly used in tank fabrication and many other long-lasting fabricated structures.

Polypropylene – Polypropylene is a non-contaminant Grey (Biege) thermoplastic. With its rigid and glossy surface, polypropylene is approved for direct food contact and is suited for environments where bacteria containment is important.

Polyurethane – In the family of elastomers, polyurethane is a “flexible” polymer that can support very large degrees of flex to return quickly and almost completely in its original shape. Because of this, Polyurethane has a high impact and tear resistance.

uPVC / cPCV – uPVC (Unplasticised Polyvinyl chloride) and cPVC (Chlorinated polyvinyl chloride) are highly chemically resistant and very versatile thermoplastics, rigid and heavy (for plastic) uPVC and cPVC are similar in their composition but differ when it comes to temperature service range (cPVC is for high temp applications).

Recycled Plastics – Regrind, Regen and Blended polymer sheets offer eco-friendly recycled plastic sheets near as good as the original virgin products they have been harvested from. These green products are great for the environment by finding uses where newly manufactured sheets are not required. Recycled plastics stand out as a strategic choice for eco-friendly businesses where virgin polymer sheet is of lesser importance.

UHMWPE – UHMWPE is a sliding/wear material great for flow promotion. Recent developments allow some grades to be welded by hot air welding processes. Several colours and grades are available including natural (white), black static dissipative, black UV resistant, green self-lubricating, recycled and high temperature resistant.

Other – Other plastic sheet and materials available on the local Australian market and supplied by Industrial Plastics include; ACP (Aluminium Composite Panel), ASA (Acrylonitrile Styrene Acrylate), Canvas Bakelite, HIPS (High Impact Polystyrene), PEEK, PETG, Polysulphone, PTFE (Teflon), and Fiber-Reinforced Plastic (FRP).